Sustainable Manufacturing

Real-time energy management and scheduling based on LLM + IO

Manufacturing plants are major energy consumers with complex and dynamically changing energy flows. A key element of sustainable manufacturing is real-time, precise energy scheduling to handle volatile electricity prices, intermittent renewable generation, and changing production demands. Traditional energy-management systems lack automation and struggle to perform multi-objective coordinated optimization.

This proposal builds an integrated energy “brain” of sensing → forecasting → optimization → execution. The LLM plays the sensing and forecasting roles: it analyzes unstructured textual inputs such as weather forecasts (which affect shop-floor temperature control), production schedules, and grid demand-response signals to accurately predict factory load and on-site renewable (e.g., rooftop PV) generation over the next hours or days. Then the intelligent optimization (IO) algorithm takes over to make optimization decisions: targeting minimal total energy cost and minimal carbon emissions while meeting production deadlines, it dynamically adjusts shiftable loads (e.g., washing and testing tasks), the on/off timing of high-power equipment, and the charge/discharge strategy of energy-storage systems in real time.

For example, on foreseeing an afternoon price peak and a grid peak-shaving request, the system can automatically postpone electroplating to nighttime and draw power from battery energy storage, thereby lowering electricity costs and participating in grid ancillary services to support system-level stability. This LLM–IO synergy elevates energy management from passive monitoring to active optimization, achieving both economic and environmental benefits and serving as a core pillar of a green transformation for intelligent manufacturing plants.

Artificial Intelligence Techniques for Sustainable Reconfigurable Manufacturing Systems: An AI-Powered Decision-Making Application Using Large Language Models

This study presents a pioneering AI-enabled framework using fuzzy logic and LLMs to evaluate techniques for sustainable reconfigurable manufacturing, identifying machine learning and big data analytics as the most promising.

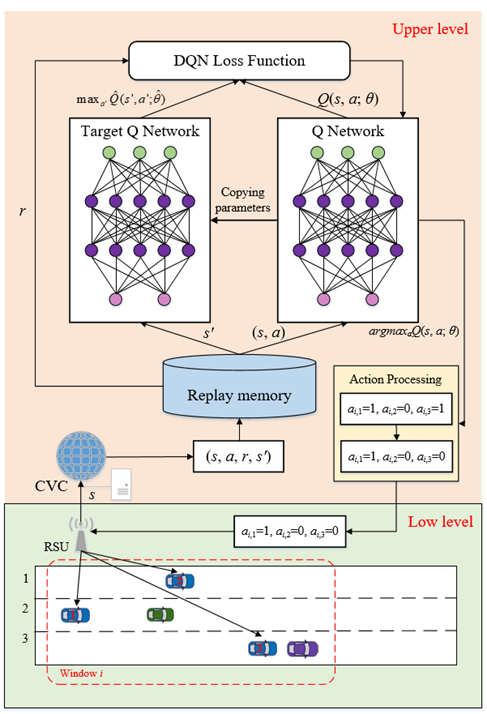

Integrated Control Strategies for Freeway Bottlenecks with Vehicle Platooning

This work proposes a hybrid framework (VSL-VP) that combines variable speed limits and CAV platooning, optimized by deep reinforcement learning, to enhance throughput and alleviate congestion at freeway bottlenecks.

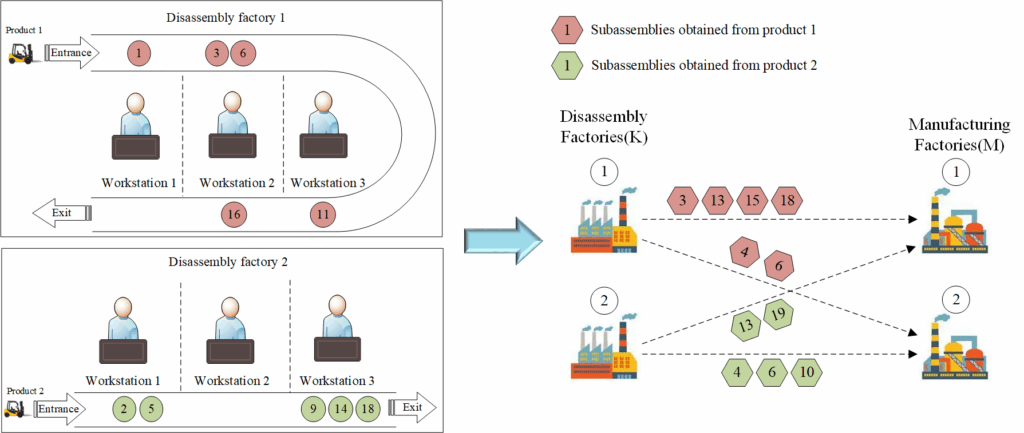

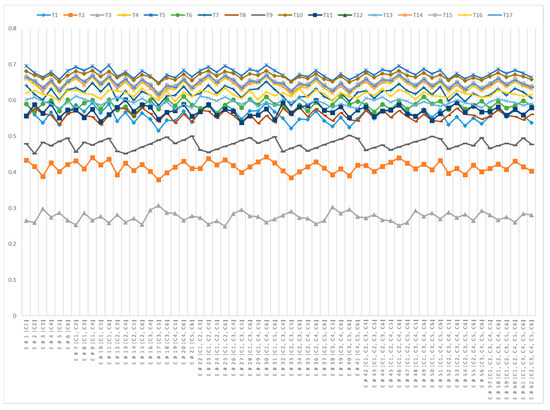

Multi-Objective Integrated Energy-Efficient Scheduling of Distributed Flexible Job Shop and Vehicle Routing by Knowledge-and-Learning-Based Hyper-Heuristics

This paper proposes a novel knowledge-and-learning-based hyper-heuristic algorithm to solve integrated scheduling and routing problems, minimizing makespan, energy consumption, and workload across distributed factories.

Multi-Objective Optimization of Multi-Factory Remanufacturing Process Considering Worker Fatigue

This work optimizes multi-factory remanufacturing by modeling worker fatigue, using a discrete battle royale optimizer to simultaneously maximize profit and minimize health risks.