Sustainable Manufacturing

Human–machine collaborative sustainable design and closed-loop supply-chain optimization

The ideal of sustainability is to embed “green” attributes at the product lifecycle’s starting point — the design phase — and to build a closed-loop supply chain that enables resource circulation and regeneration. Yet designers often lack comprehensive knowledge of materials’ environmental properties, and supply-chain planners struggle to simulate complex, dynamic circular-economy networks.

This perspective proposes a human–machine collaborative innovation environment powered by an LLM. In product design, a designer can make natural-language requests to an LLM assistant (for example, “find a biodegradable alternative material with comparable strength for this phone casing”). The LLM queries built-in green-materials databases and academic literature, recommends alternatives (e.g., high-performance bio-based plastics), and compares their mechanical properties, cost, carbon footprint, and recyclability to inspire design choices and reduce environmental impact at the source.

At the supply-chain level, the LLM and intelligent optimization algorithms jointly construct a digital-twin simulator. The LLM consolidates and interprets textual information about macroeconomic policy, market trends, and consumer recycling behavior to forecast external changes. Under rules and constraints defined by the LLM, IO algorithms dynamically optimize the complex closed-loop supply network — including forward manufacturing and distribution and reverse processes such as collection, remanufacturing, and resale — to identify operating strategies that maximize resource utilization, minimize total cost, and reduce carbon emissions. This enables enterprises to confidently respond to risks such as “green tariffs” and material shortages, and to advance toward a true circular economy.

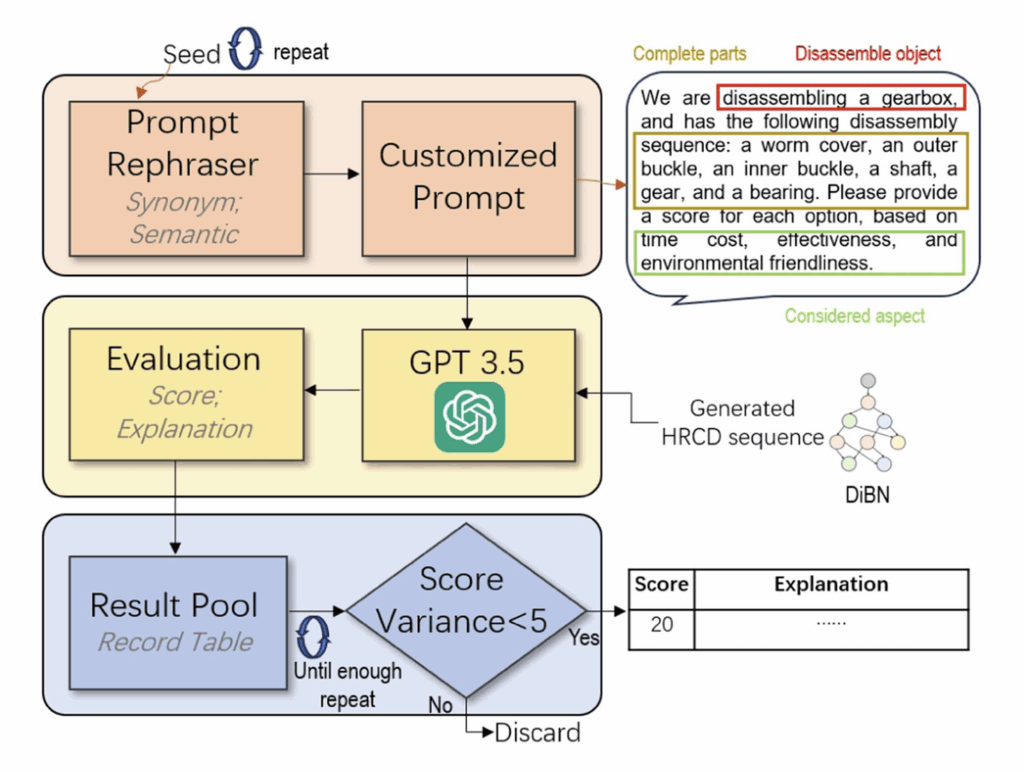

Leveraging Large Language Models to Empower Bayesian Networks for Reliable Human-Robot Collaborative Disassembly Sequence Planning in Remanufacturing

This paper introduces an AI-driven framework that combines a Dirichlet Bayesian Network and a fine-tuned LLM to generate and evaluate optimal disassembly sequences for human-robot collaboration, effectively managing uncertainty.

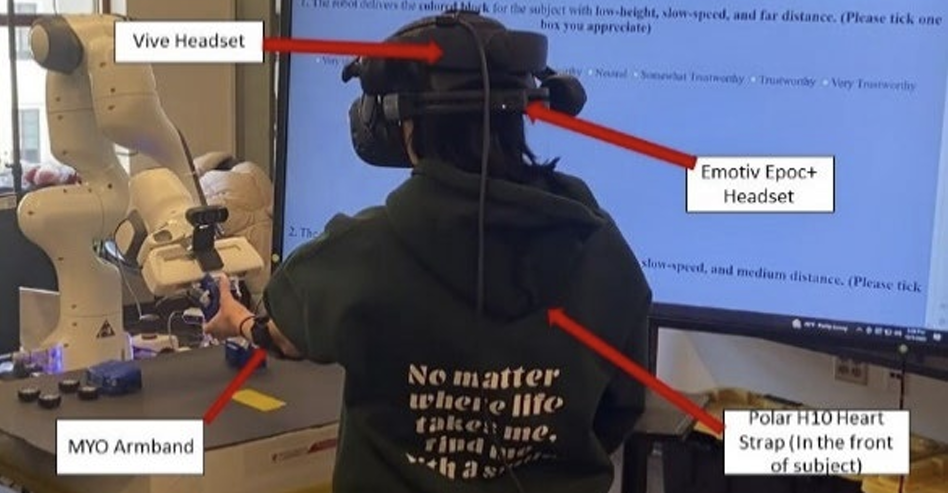

Characterization of Human Trust in Robot through Multimodal Physical and Physiological Biometrics in Human-Robot Partnerships

This research builds computational models to quantitatively characterize human trust in robots during collaboration, using unique physical and physiological data from the TrustBase dataset.

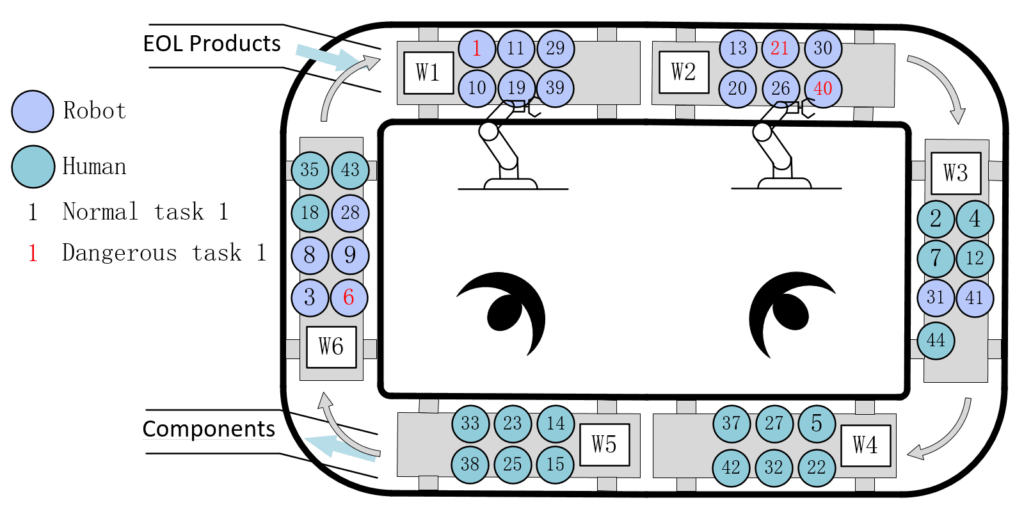

Human-Robot Collaborative Disassembly Profit Maximization via Improved Grey Wolf Optimizer

This paper proposes a human-robot collaborative circular disassembly line to handle complex products, using an improved grey wolf optimizer to maximize profit where traditional solvers fail.

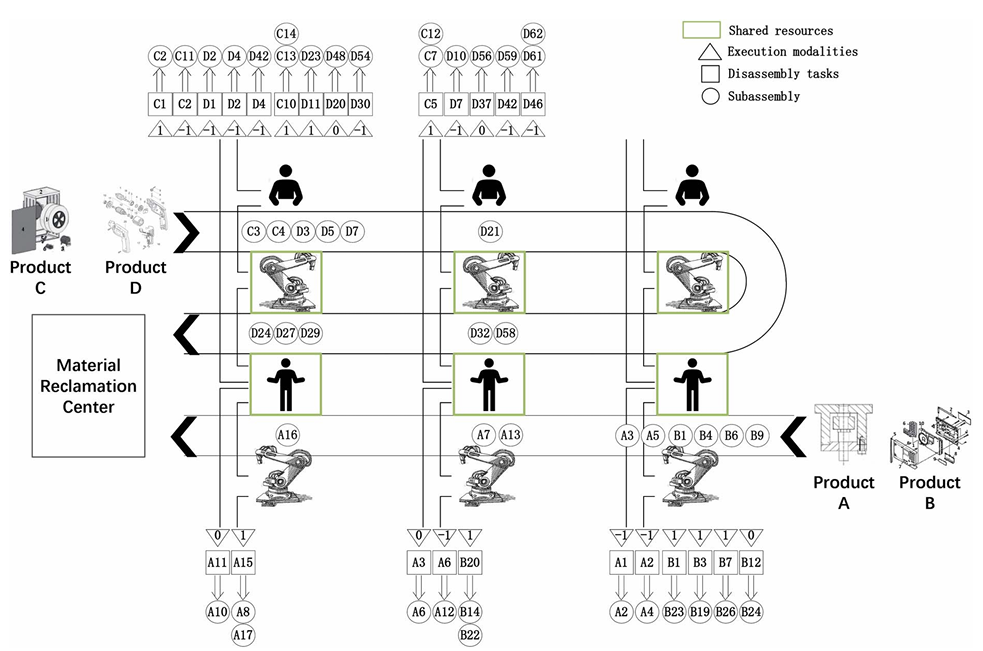

Modeling and Optimization of Multiproduct Human–Robot Collaborative Hybrid Disassembly Line Balancing With Resource Sharing

This study proposes a hybrid disassembly line where labor is shared across lines to prevent redundancy, using a discrete aquila optimizer to maximize profit and outperform other algorithms.