Sustainable Manufacturing

LLM-based production-process analysis and carbon-emissions traceability

A primary challenge to sustainable manufacturing is precise quantification of environmental impact; the core difficulty is that more than 80% of sustainability-relevant data across the manufacturing value chain (e.g., equipment maintenance logs, quality-inspection reports, purchase orders, energy bills) exist as unstructured text. Traditional approaches depend on manual collation and accounting, which are inefficient, error-prone, and hard to make real-time, resulting in lagging and imprecise carbon-footprint management.

This perspective leverages the LLM’s superior text-understanding and information-extraction capabilities to build an end-to-end automated carbon accounting and analysis platform. The system automatically extracts key activity data (such as material types and quantities, transport mileage, equipment runtime, and energy-meter readings) from documents, databases, and logs across departments. The LLM can understand contextual meaning in text — for example, it can infer from a maintenance record that “the machine idled for 2 hours” constitutes an energy-waste event, and correctly classify and quantify it. All extracted structured data are automatically fed into Life Cycle Assessment (LCA) models or carbon-accounting engines, dynamically generating precise carbon-footprint maps down to the product, order, or production-batch level.

Moreover, the LLM can act as a “sustainability analyst.” When the system detects anomalous emissions, the LLM can trace root causes across data sources and produce analytical reports (for example, “this month’s emission exceedance is primarily due to Supplier A’s aluminum raw material having higher-than-average carbon intensity”). This enables firms to move from macro accounting to micro process analysis, achieving transparent, traceable carbon-footprint management, providing accurate data support for mitigation measures, and automatically producing ESG reports that meet regulatory or stakeholder requirements.

A Multiobjective Discrete Harmony Search Optimizer for Disassembly Line Balancing Problems Considering Human Factors

This study optimizes disassembly line balancing by integrating human postures (sitting/standing), using a multi-objective model and a novel Pareto-based discrete harmony search algorithm to maximize profit while minimizing worker fatigue.

Large language model-driven multi-agent systems for improving production efficiency and reducing carbon emissions in manufacturing

We propose CarbonDTMAS, an LLM-enhanced digital twin multi-agent system, to tackle carbon emission and dynamic scheduling in customized manufacturing, achieving superior results in tardiness, workload, and emissions.

Robust Control of Failure-Prone Manufacturing Systems With Assembly Operations

This work breaks from the ideal-system assumption to propose a robust deadlock control policy for failure-prone AMSs with assembly operations, introducing four key properties and a novel Banker’s algorithm-based solution.

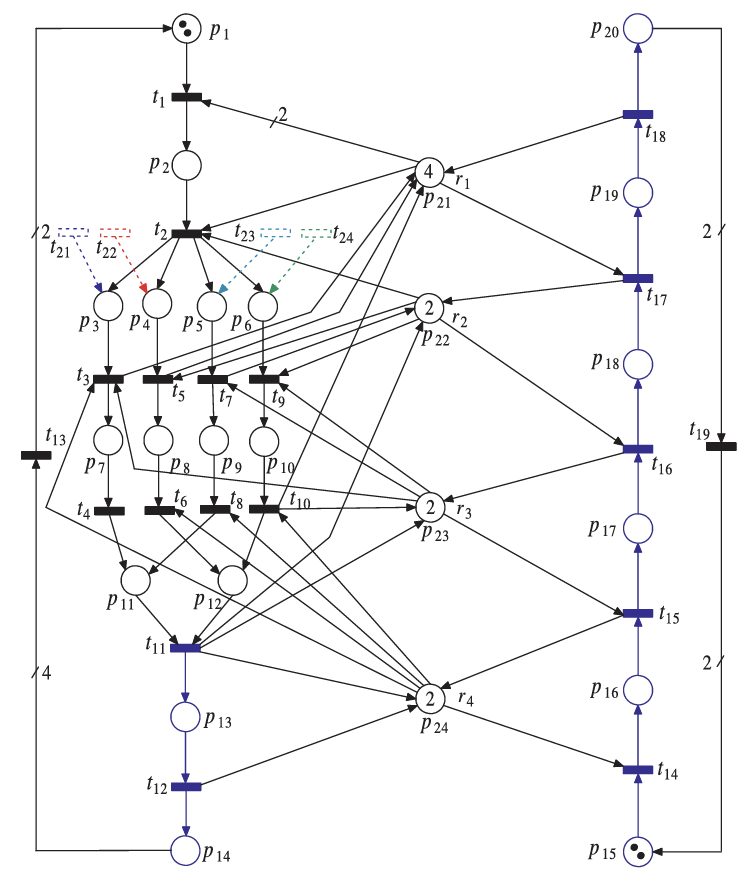

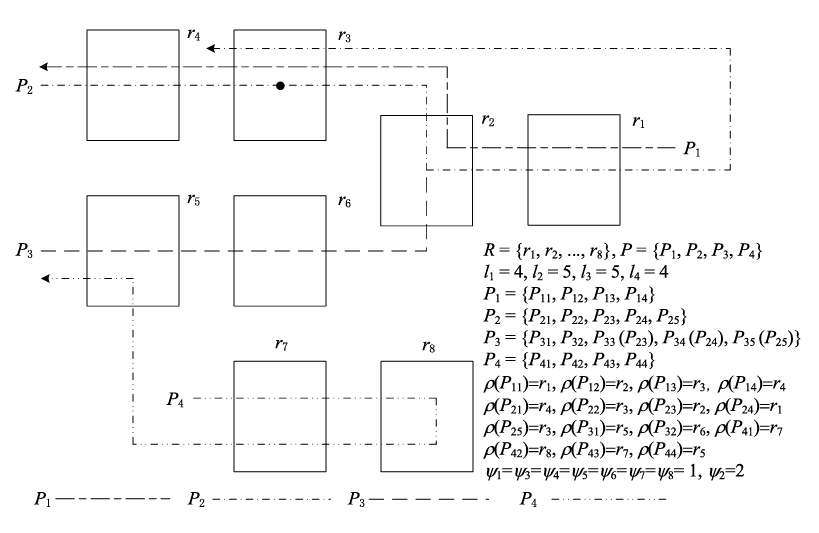

Deadlock Analysis and Avoidance for Automated Manufacturing Systems Based on Petri Nets With Forward-Conflict-Free Structures

This paper presents a novel structural characterization of deadlocks in Petri nets with batch assembly, proposing a necessary and sufficient condition for liveness and a real-time hierarchical control algorithm.